Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

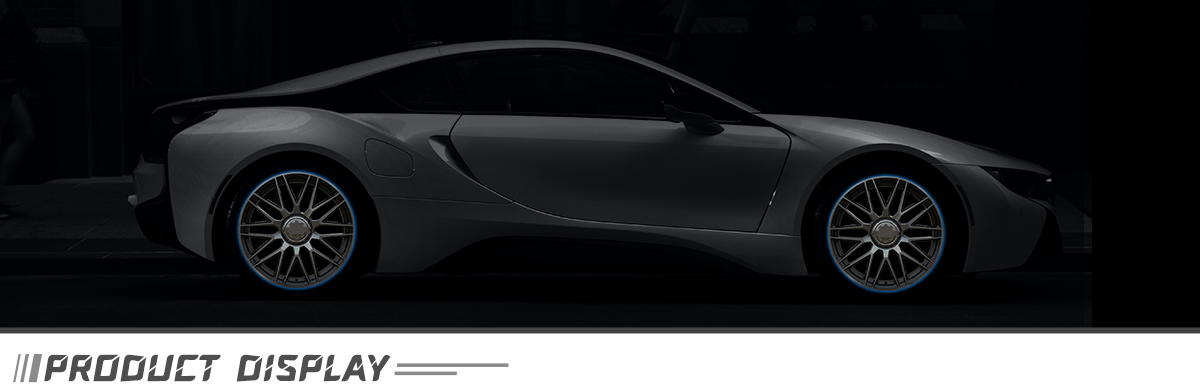

Matte black alloy wheels for 2022 NEW BMW X6M

We are certificated manufacturers with stable quality. All wheels are carefully designed and machined with optimal performance as a priority, in order to reduce overall weight without sacrificing any of their integral strength.

FITMENT SIZE ET PCD CB

BMW X6M 1985 25-35 5*112/120 66.5/74.1

BMW X6M 1995 30-40 5*112/120 66.5/74.1

BMW X6M 2095 35-40 5*112/120 66.5/74.1

BMW X6M 20105 35-40 5*112/120 66.5/74.1

BMW X6M 2110 35-40 5*112/120 66.5/74.1

BMW X6M 2111 35-40 5*112/120 66.5/74.1

BMW X6M 2210 35-40 5*112/120 66.5/74.1

BMW X6M 2211 35-40 5*112/120 66.5/74.1

The main advantages of aluminum wheels are lightweight, toughness and high performance. In addition, they are cheap, durable and easy to maintain. They can last more than 20 years if they are well maintained. Therefore, many car owners use them as original car wheels instead of steel wheels. Used by professional car racers, many world-famous teams are also available in their best racing cars. The aluminum alloy wheels are not only durable, but also have a relatively good strength and toughness. At the same time, the weight reduction of aluminum alloy wheels makes it possible to help improve the fuel consumption of automobiles.

1.Features of Matte black alloy wheels for 2022 NEW BMW X6M

Due to its material and manufacturing process, a steel wheel has poor stability at high speed; conversely, an aluminum alloy wheel has great stability and improved acceleration and heat dissipation.

2.Advantages

We are certificated manufacturers with stable quality. All wheels are carefully designed and machined with optimal performance as a priority, in order to reduce overall weight without sacrificing any of their integral strength.

3.Our Transportation

Our company can provide shipping methods for all channels of sea, rail, land, and air. Sea freight takes the longest time but is the cheapest, and air freight has the best timeliness but is the most expensive.

4.The difference between aluminum alloy wheels and steel wheels

Material comparison

1. In fact, aluminum alloy wheels actually contain other metals, such as iron, etc., so they should be called aluminum alloy wheels. Compared with ordinary aluminum alloy wheels, iron wheels have good toughness and poor hardness, while aluminum alloy wheels are the opposite, with good hardness but poor toughness. Due to the material and process of manufacture, the steel wheel has poor stability at high speed, while the aluminum alloy wheel has good stability at high speed, and the acceleration and heat dissipation of the aluminum alloy wheel are also better.

2. Therefore, we will find that the steel rim does not change in appearance after going through the potholes on the road, but it will start to shake when the speed is close to 100 mph, mainly because it is made of stamping. , the mass counterweight is uneven, so the speed will inevitably cause rotation. The aluminum alloy ring does not have such a phenomenon, because the aluminum alloy ring is cast and formed, and it is necessary to detect the internal holes and turn the blank outside. The contour and mass counterweight are relatively accurate and average, and the aluminum ring is lighter in weight and can be made thicker than the steel ring, which also greatly improves the acceleration performance of the car. In addition, the heat dissipation capacity of the aluminum ring is better than that of the iron fist, which will also add points to the braking performance

Actual use comparison

1. Although the overall performance of aluminum alloy wheels is better than that of iron wheels, but after all, its cost is relatively high. It also costs thousands of yuan to replace a set of general aluminum alloy wheels. At the same time, the post-maintenance of aluminum alloy wheels is also more troublesome than iron wheels. For example, if you don't mind driving, it is very easy to bruise the aluminum alloy wheel, get on the road, increase the isolation belt, isolation pier, etc., which is the most likely to damage the aluminum alloy wheel. And once the aluminum alloy wheel is damaged, it can only be replaced, and the original appearance and maintenance cannot be restored.

2. Steel hubs are equipped with plastic hubcaps. There are many beautiful hubcaps on the market now, and if they are matched properly, they can also achieve the same effect as aluminum alloy wheels.

Aluminum alloy wheel repair method

1. Repair of hub deformation:

This technology refers to the application of professional technology and tools to solve the problems of wheel hub wear, fracture, notch, corrosion, depression and distortion without destroying the molecular structure and mechanical properties of the aluminum alloy.

2. Wheel surface refurbishment:

This technology is to use professional technology and materials to repair and refurbish the wear, scratches, fading, small defects, etc. according to the material characteristics of the wheel hub surface.

3. Wheel color change:

Wheel color change is to provide personalized wheel surface refurbishment and color change services according to the needs of different customers.

4.Polished wheel repair:

The surface of the polished wheel has a natural metal texture, bright luster, smooth and clean appearance, and strong visual aesthetics. However, the refurbishment of the polished wheel requires special techniques and skills, and requires professional polishing equipment and materials.